Polo Latest

The Power of RF Sealing: Creating Airtight, Waterproof, and Durable Solutions for Demanding Environments

In industries where product integrity is non-negotiable—from life-saving medical devices to mission-critical defense equipment and robust industrial solutions—conventional manufacturing methods often fall short. This is where Radio Frequency (RF) Sealing emerges as a transformative technology. Unlike traditional methods, RF sealing creates bonds that are not just strong, but truly airtight, waterproof, and exceptionally durable, designed to meet the demands of all the industries we serve. For over 77 years, Polo Custom Products has leveraged specialized processes like RF Sealing to deliver uncompromising quality and reliability, understanding the critical needs of (OEMs).

Understanding RF Sealing: Precision Through Internal Heat

Also known as High-Frequency (HF) welding or Dielectric welding, RF sealing is a sophisticated process that joins thin sheets of polar thermoplastic materials using high-frequency electromagnetic energy. Instead of applying external heat, RF energy causes polar molecules within the material to rapidly reorient, generating heat

internally through molecular friction. This internal heating allows the material to soften and melt evenly under precise pressure between two dies, creating a seamless, molecular bond.

This internal heating mechanism offers a significant advantage over other bonding techniques. Unlike traditional sewing, which creates perforations and weak points. RF sealing ensures a consistent, homogeneous fusion. The resulting weld seam is often stronger than the original material itself, providing a higher safety factor and extended lifespan for products.

The Unrivaled Advantages of RF Sealing for OEMs

RF sealing offers compelling benefits that address stringent manufacturing requirements:

- Durability & Integrity: RF welding creates heavy-duty joints highly resistant to tears and rips, often surpassing the strength of the base material. The seamless bond ensures truly airtight, watertight, and gas-tight seals, which is non-negotiable for fluid containment, environmental protection, or maintaining sterile barriers.

- Consistent & Scalable Production: As a repeatable, precise process, RF welding leads to consistently strong and reliable welds with minimal variation. Its automated nature allows for faster production cycles and reduces manual labor compared to traditional methods. It also produces a clean, professional appearance with no threads or perforations, reducing thermal distortion for precision seams.

- Broad Material Compatibility: While primarily effective with thermoplastics containing polar molecules like Polyvinyl Chloride (PVC) and Polyurethane (PU), RF sealing can also be adapted for certain nylons, PET, EVA, and some ABS resins under specific conditions . Polo Custom Products also specializes in working with specialty formulation materials, including medical-grade, DEHP-free, latex-free, water-resistant, mildew-resistant, chemical-resistant, UV-resistant, puncture-resistant, antimicrobial, and cold crack-resistant films. This includes a special grade of polyolefin developed in response to impending restrictions on PVC use.

Real-World Impact: Where Polo’s RF Sealing Excels

Polo Custom Products applies its RF sealing expertise across a multitude of sectors, delivering high-performance solutions:

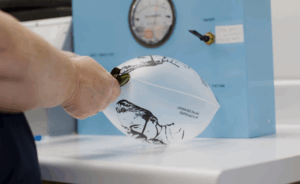

- Medical & Healthcare: RF-sealed products are crucial for sterile, leak-proof fluid containment systems like IV bags, blood pressure cuffs, External Catheters, and fluid collection bags. Polo also manufactures inflatable medical devices and contamination bags, ensuring critical functionality and patient safety.

- Fire & Safety: For heavy-duty industrial applications, RF sealing provides robust protection for custom protective covers, test equipment carrying cases, and containment solutions that must withstand harsh environments.

- Government & Defense: As a trusted, Berry-compliant supplier, Polo delivers high-quality, durable components for military and defense operations. RF sealing is vital for products such as fuel bladders, protective suits, oxygen cylinder sleeve bags, and inflatable structures requiring unwavering reliability in extreme conditions .

- Aviation & Powersports: RF sealing creates the airtight bonds essential for maintaining functionality and durability in outdoor and recreational gear, from air mattresses to life vests and inflatable boats.

Partnering with Polo Custom Products: Your Strategic Advantage

With over 77 years in custom manufacturing, Polo Custom Products brings unparalleled expertise to every project. The company offers end-to-end service, encompassing engineering, product development, and design, ensuring product manufacturability, quality, and regulatory compliance from concept to delivery. Polo Custom Products is ISO 9001:2015, ISO 13485:2016, HubZone, and ITAR registered.

Polo’s in-house testing laboratory provides an additional layer of quality assurance, performing pressure decay leak testing, digital tensile strength, and inflation and burst strength testing. Strategically positioned for high-volume production and scaling, Polo is supported by three domestic manufacturing facilities and five global manufacturing partners. An extensive network of over 440 active raw material and specialty formulation suppliers across 18 countries ensures the procurement of virtually any material a product may require. This comprehensive approach simplifies complex projects and offers significant supply chain advantages for OEMs.

Conclusion: Build Your Next Innovation with Confidence

In today’s demanding markets, the performance and reliability of products are non-negotiable. RF Sealing offers a proven path to achieving superior airtight, waterproof, and durable solutions that withstand the toughest conditions. When partnering with Polo Custom Products, OEMs gain more than a manufacturer; they gain a strategic ally with decades of expertise, advanced capabilities, and a relentless commitment to quality. Let Polo Custom Products help transform your product vision into a market-ready reality with the power of RF Sealing.

Contact Polo Custom Products today to discuss your project and discover how advanced manufacturing solutions can elevate your next innovation.