What We Do

RF Welding Services

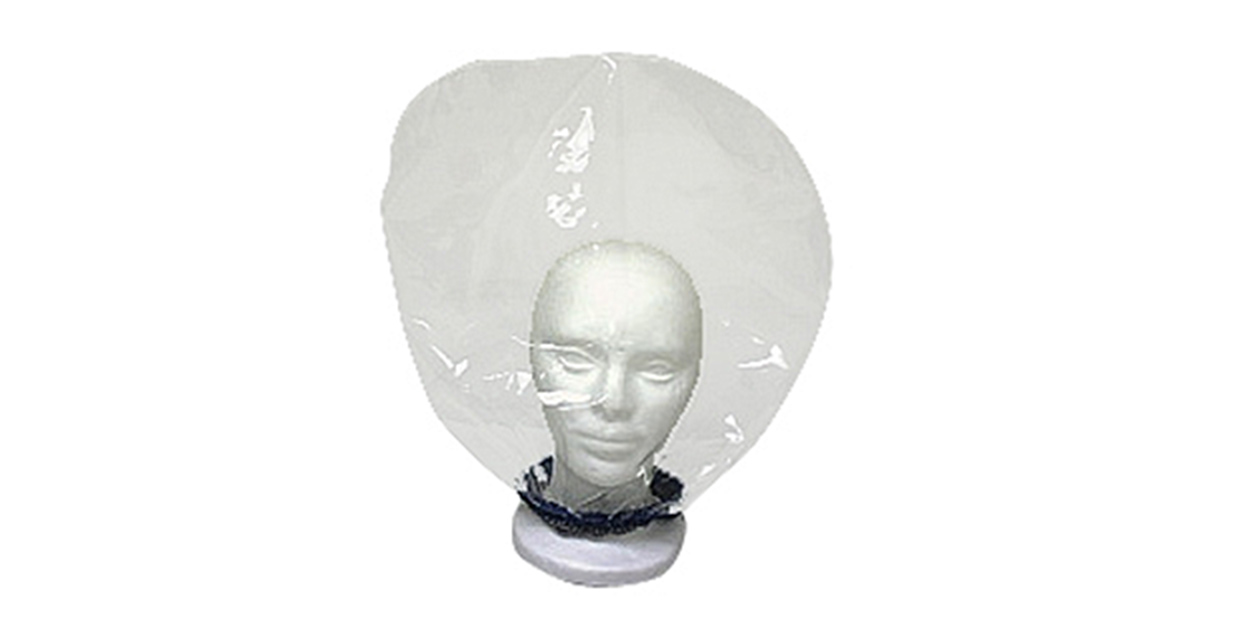

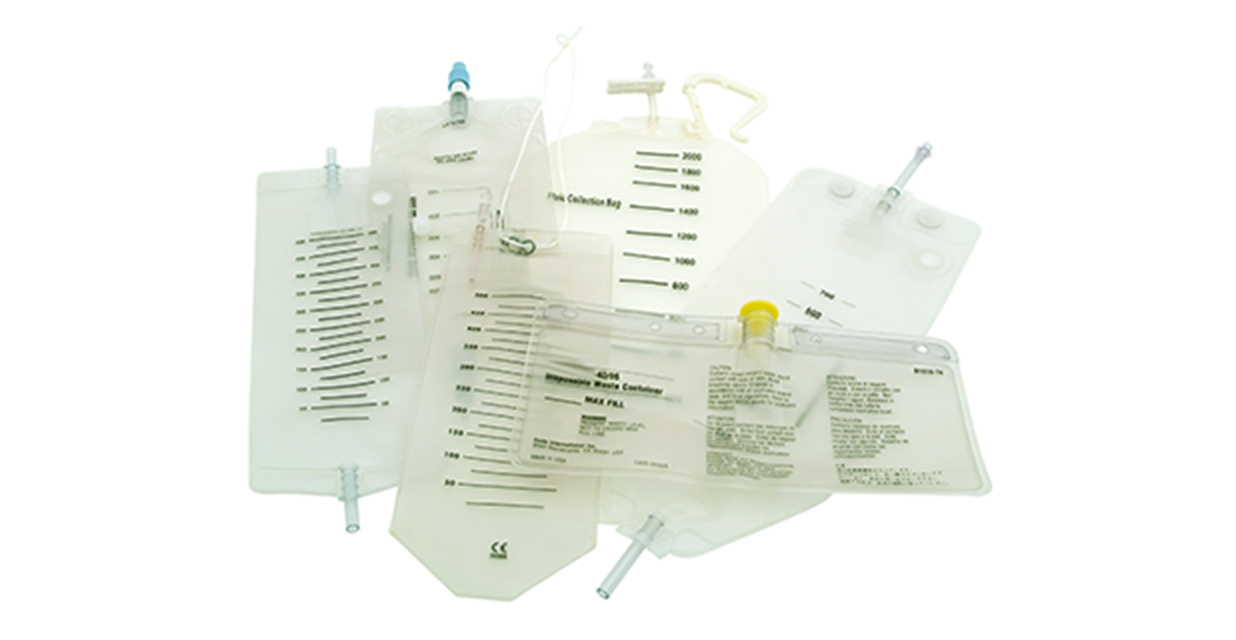

Polo Custom Products specializes in RF welding services for OEMs, also known as High-Frequency welding or Dielectric welding. We also offer Impulse sealing, Ultrasonic sealing, and Thermo-Contact sealing. We manufacture custom-sealed products such as Medical Class I and Medical Class II drainage and body fluid collection bags, ostomy, nephrostomy, and colostomy bags, laparoscopic surgery specimen collection bags, compression arm wraps and cuffs, passenger oxygen mask assemblies, CBRN safety hood assemblies, and other inflatable air bladders and cushions using vinyl, urethane, EVA and olefin films. Our global supply network also provides you with specialty formulation materials such as class VI medical grade vinyl, DEHP-free vinyl, latex-free vinyl, water resistant, mildew resistant, chemical resistant, UV resistant, puncture resistant, antimicrobial, cold crack resistant, and other specialty films.

Click below to see any current news or Contact Us with any questions regarding our RF Welding Services!

RF Welding & Sealing Product Solutions

Our extensive RF welding & sealing product solutions work well with our secondary manufacturing operations, such as valve sealing and tube installation, tube gluing, and hardware attachment. Our in-house design and engineering capabilities allow for the development and procurement of non-core components that work in conjunction with a sealed component. Examples include injection molding, blow molding, metal stamping CNC machining, specialty packaging, and others.

Polo Custom Products is ISO 9001:2015, ISO 13485:2016, HubZone, and ITAR registered. Testing and inspection of sealed products occurs at every step of the manufacturing process to ensure your product functions to your exact requirements. Our in-house testing laboratory offers you another level of quality assurance with pressure decay leak testing, digital tensile strength, and inflation and burst strength testing. We will also work with you to set up other testing equipment and protocols as needed.

We offer many different types of RF welding and sealing services, including:

Let Polo Custom Products manage all aspects of your RF-sealed product needs. We have the design, engineering, and manufacturing capabilities you need to develop a quality, cost-effective sealed product.

Contact Us or Request a Quote Today and ask about our impulse sealing, ultrasonic sealing, thermo-contact sealing, and radio frequency sealing/welding services.

Frequently Asked Questions

What are the benefits of RF welding compared to other welding methods?

RF welding is a very effective plastic welding process that offers equivalent weld characteristics to impulse welding, ultrasonic welding, hot air welding or thermal contact welding. RF welding allows for complex 2D patterns that are not achievable using the other methods previously mentioned welding methods. 3D molded parts such as tubes or valves can be welded into assemblies, depending on the part geometry. Tooling is less expensive and easier to maintain compared to the other welding methods. Once a weld process is dialed in, the process is very consistent. RF weld cycle times, product complexity dependent, can be very fast.

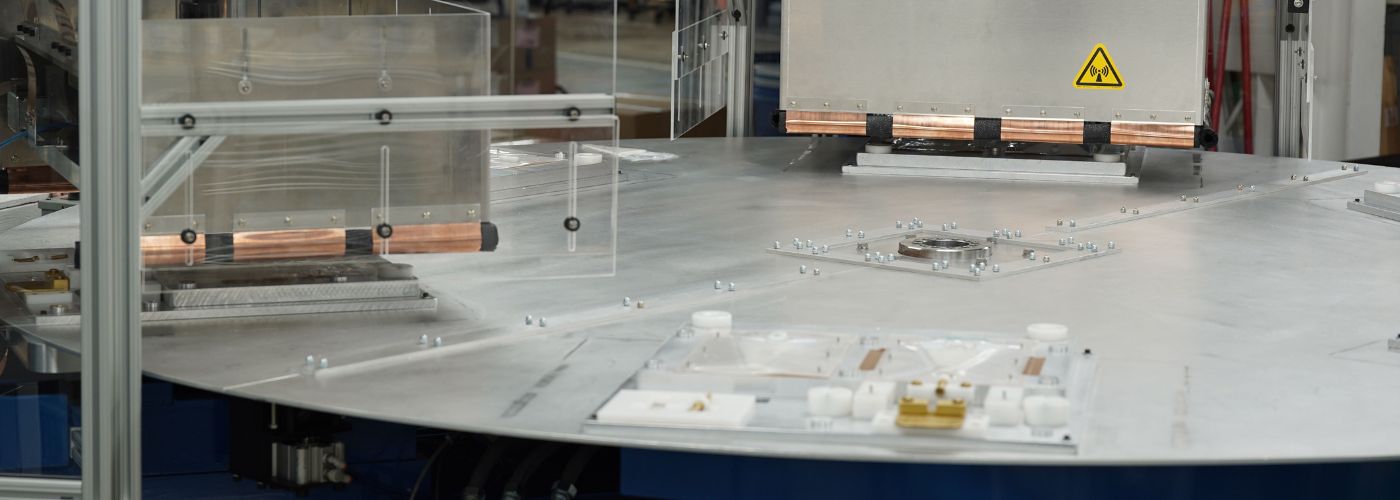

How does the RF welding process work?

Plastic films that are made from polar molecules are used, such as PVC, TPU or PET. These films are loaded into an RF welding tool that consists of an upper and lower die and tray that are made from Aluminum or Brass with the desired weld pattern machined into the Tooling. This weld pattern is welded into the plastic film layers creating the desired 2D shape, but specialty items can be welded into products, such as one way valve, molded components and simple inlet or outlet tubes.

Radio frequency, or High-frequency radio waves, are generated in the Press and broadcasted through the closed tooling. The RF waves cause the polar molecules to rotate at 27.12 MHz, which generates friction between the molecules within the weld area. The RF tools and press applies pressure to the film materials along the weld pattern while they are extremely hot, which welds the materials together under heat. After the RF waves are turned off, the material cools quickly allowing the welded parts to be handled immediately after the weld cycle is complete.

How does RF welding ensure product quality and durability?

RF welded products have been in use for decades in a variety of application ranging from simple embossing to critical lifesaving medical products. Equipment is fitted with alarms that will trigger if any sort of manufacturing fault occurs during the welding process. The welding process causes the plastic in the welded areas to “flow” into one another, essentially becoming one material, as opposed to two separate film layers. If welded films are loaded onto a tensile tester, it is expected to see the base film material break before the welded are fails, which signifies a functional weld.

Are there any limitations to RF welding?

The materials being welded need to be comprised on polar Molecules.

Perimeter weld tools are milled flat but allow you to create complex shapes on those 2D planes, resulting in the complex shapes getting welded onto the film layers.

Inlet and outlet tube, one-way valves, or molded parts can be incorporated into the product design (i.e., recreational pool floatation devices.) Inlet or outlet tube welds can be incorporated into the perimeter weld tooling, instead of needing a separate tool.

What should I consider when designing a product for RF welding?

Select one material that is RF welding compatible for the welded product. This consists of polar molecules like PVC or TPU. PVC or TPU coated fabrics work well and offer exceptional functional properties.

Screen printing or hot stamping can be incorporated into the film layers before welds are completed.

Film layers need to fully cover the tools weld area or weld issues will be created. Typically, the cut pieces are 1/4” larger than the weld pattern, at a minimum, to prevent weld issues. The excess film material can remain after the weld is completed, or it can be trimmed away in an offline operation, if desired.

The welded area will have a higher tensile strength than the adjacent unwelded portion of the product. A large weld width does not increase the product strength.

If your product is intended to be pressurized, any corners should have a large radius to reduce the pressure from concentrating on that specific point, which can cause failures.

Typical testing methods for RF welded products consists of tensile testing, pressure decay testing or burst testing.

What We Do

Custom Since 1947

In addition to our RF sealing and other heat sealing capabilities, Polo Custom Products has the ability to design and procure non-core components. Examples include injection molded or blow molded trays and tubs, metal stamped brackets, CNC machined parts, specialty packaging and others.

We're all you need.

Turn to us, we are experts in RF sealing and other heat sealing processes.